Components for all sectors.

For you.

We are the partner

that makes the difference.

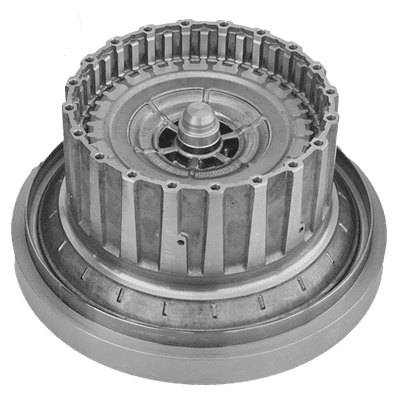

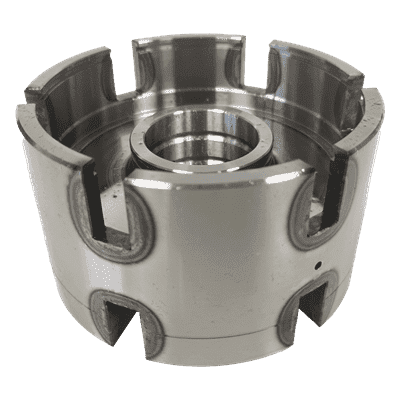

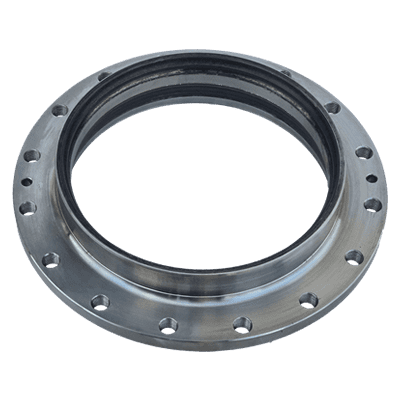

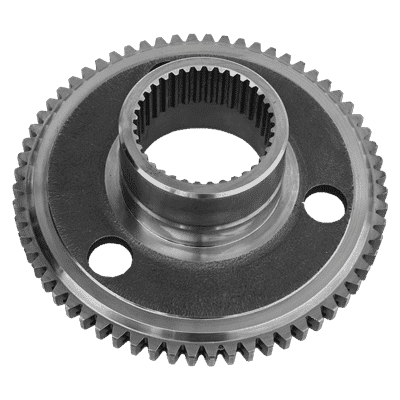

We manufacture the finish parts for the end customer directly from the raw materials (bars, tubes, forgings, plates, etc). Our production system is extensive, automated and equipped with state-of-the-art CNC machines, such us lathes and milling machines able to process soft and hard machining with a component dimension range span from 100 mm to 750 mm.

Our production consists in a “five steps” process, but the extent of our machinery portfolio allows us to take charge of a single process rather than create an assembly of a finished product, for any industrial sector.

APPLICATION SECTORS

Automotive

Learn more

Learn more Heavy Vehicles

Learn more

Learn more Marine

Learn more

Learn more Off-road

Learn more

Learn more Robotics

Learn more

Learn more Agricultural machinery

Learn more

Learn more Railway Applications

Learn more

Learn more Renewable energy

Learn more

Learn more Industrial applications

Learn more

Learn more Construction Machinery

Learn more

Learn more Innovation and Reliability

In industrial sectors, M4U excels as a pillar of innovation and reliability. Our work dedication, the passion for engineering and our focus on component performance and functionality result in state-of-the-art solutions that ensure our partners confirm their market leadership. By choosing M4U, you rely on a partner to jointly deal with the today’s technical challenges and to jointly work on setting the tomorrow standards.

Sustainability and Efficiency

M4U’s commitment to sustainability is driven by promotion of innovative technologies to reduce environmental impact and to optimize the use of resources. In harsh environment, such as construction and transport, for example, collaborating with M4U means choosing a future where efficiency and respect for the environment come together.

Partner in product development

M4U is not just a supplier. We aim to be a true partner for a joint development without customers, supporting them not only in solving current challenges, but also taking the lead for preparing to the future trends. Our holistic approach, together with the well-established strategic partnerships in the supply chain, enable our customers to successfully challenge the evolving technology landscape, building a more sustainable business together.

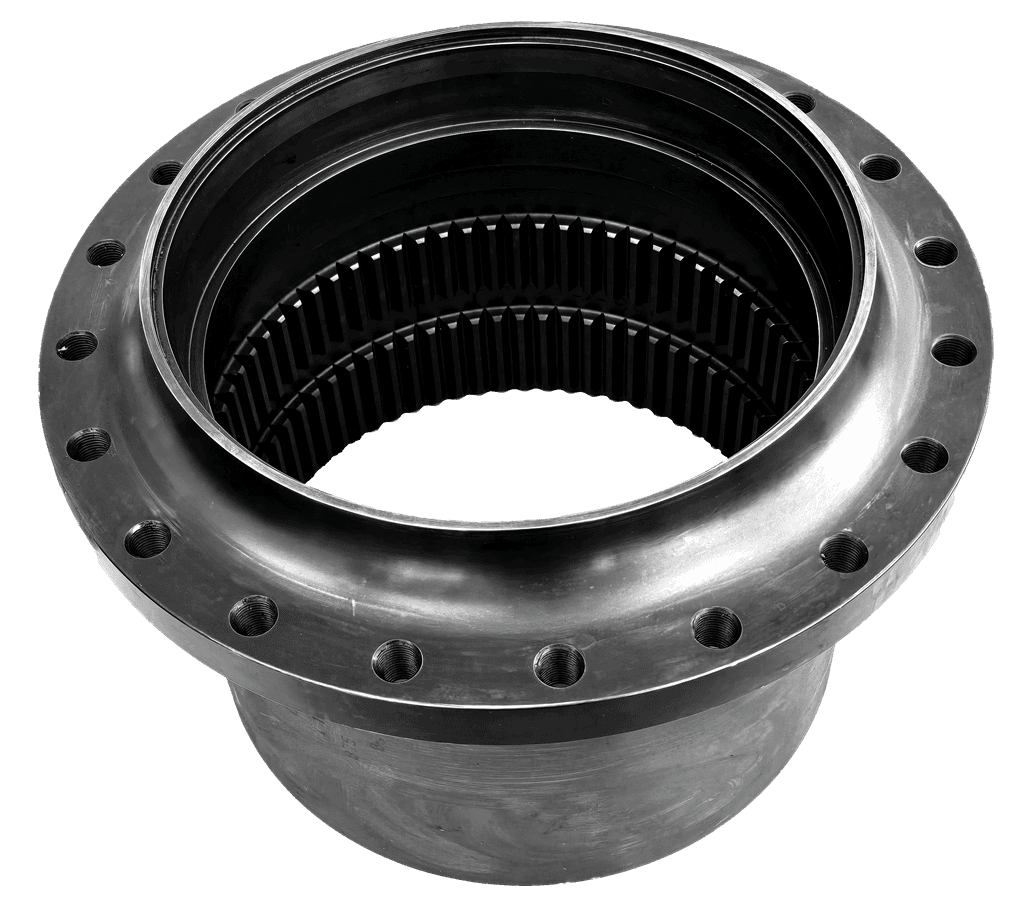

From the single part

to the assembled product.

The extent of our machinery portfolio allows us to take charge of a single process rather than create an assembly of a finished product.

We rely on a network of specialized companies and supply chain partners, to offer the more complete and the highest quality service, made out of “five steps” process.